The following summarizes the first contract between Northwestern Barb Wire Company and the union. This was written by Dana Fellows with the help of AI, to improve readability and flow.

A Historic Labor Agreement: The First Steelworkers’ Contract at Northwestern Barb Wire Company

In the midst of the Great Depression, on May 1, 1937, a groundbreaking agreement was signed between the Steel Workers Organizing Committee (SWOC) and the Northwestern Barb Wire Company. This contract marked a turning point in labor relations at the plant, ensuring wage protections, work hours, and grievance procedures for the company’s steelworkers.

A Step Toward Workers’ Rights

At the time, the U.S. labor movement was gaining momentum, fueled by President Franklin D. Roosevelt’s New Deal policies and the passage of the Wagner Act in 1935, which gave workers the right to unionize. The contract between the SWOC and Northwestern Barb Wire Company was part of this broader push for fair labor practices in America’s industrial heartland.

Wages: Then and Now

One of the most striking aspects of this contract was the wage structure. As of May 2, 1937, the basic labor rate was set at 57.5 cents per hour. For skilled and semi-skilled workers, the rate increased by 12.5 cents per hour, while learners (or apprentices) were paid 5 cents less than common laborers.

To put this in perspective, 57.5 cents in 1937 is equivalent to approximately $12.50 per hour in today’s dollars, adjusted for inflation. While this may seem modest by modern standards, it represented a significant improvement over previous conditions and provided a foundation for future wage growth in the industry.

Standardizing the Workweek

Another major victory in this contract was the establishment of an eight-hour workday and a forty-hour workweek—a standard that was not yet universal at the time. Workers who exceeded these hours were guaranteed overtime pay at time-and-a-half rates, ensuring that employees were compensated fairly for extra labor. This provision reflected the growing national movement to curb excessive working hours and improve quality of life for industrial workers.

Job Security and Seniority Rights

The agreement also introduced provisions for seniority-based promotions and job security, ensuring that length of service played a role in employment decisions. In cases of layoffs or workforce reductions, factors such as training, efficiency, and physical fitness were considered alongside tenure. While modern labor contracts have evolved, these early seniority rules laid the groundwork for future worker protections.

The Right to Organize Without Fear

A crucial element of the contract was the company’s recognition of the union as the exclusive bargaining agent for its workers. The agreement explicitly prohibited discrimination, intimidation, or coercion against employees for joining the union, a significant step in securing workers’ rights at a time when union-busting tactics were common in industrial America.

Resolving Disputes Through Arbitration

Before this contract, workers had little recourse when disputes arose. The agreement established a grievance process that allowed employees to bring workplace concerns directly to management through a structured system. If an issue could not be resolved internally, an impartial umpire—what we now recognize as an arbitrator—was brought in to settle disputes. This innovation helped reduce strikes and work stoppages while ensuring that workers had a voice in their employment conditions.

Workplace Safety: A Growing Concern

While today’s workplaces must adhere to stringent OSHA regulations, workplace safety in the 1930s was often an afterthought. However, this contract committed the company to making “reasonable provisions for the safety and health” of its workers, including protective equipment and proper ventilation. Though vague by modern standards, this clause reflected a growing awareness of industrial hazards and foreshadowed future labor protections.

The Legacy of the 1937 Agreement

This contract, set to remain in effect until February 28, 1938, laid the foundation for decades of labor negotiations at Northwestern Steel and Wire. Over the years, wage rates increased, safety measures improved, and labor rights expanded, thanks in part to the precedent set by this early agreement.

For today’s workers, looking back at this 1937 contract offers a glimpse into the struggles and victories that shaped modern labor rights. The eight-hour workday, the right to collective bargaining, and even workplace safety regulations—many of the protections we take for granted—were hard-won battles fought by union pioneers nearly a century ago.

As we reflect on this historic contract, we are reminded that labor rights are not static; they evolve with time, shaped by the needs and demands of the workforce. The 1937 agreement at Northwestern Barb Wire Company serves as a testament to the power of organized labor and the progress that can be achieved through collective action.

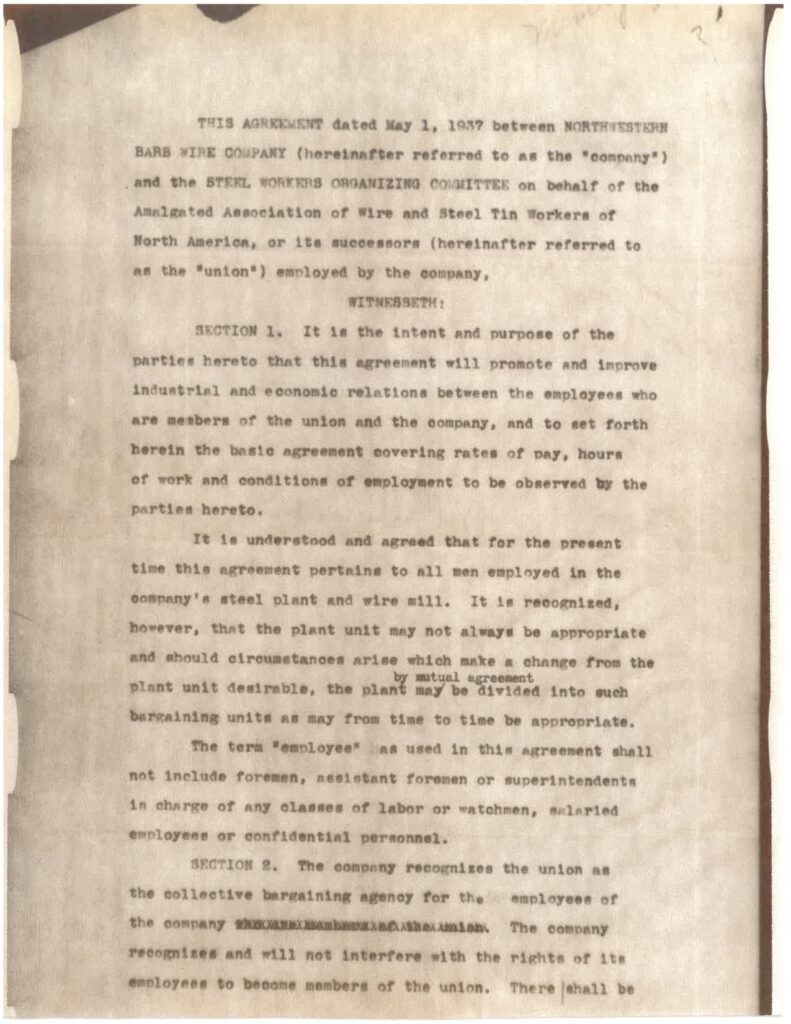

Text from Contract

THIS AGREEMENT dated May 1, 1937, between NORTHWESTERN BARB WIRE COMPANY (hereinafter referred to as the “Company”) and the STEEL WORKERS ORGANIZING COMMITTEE on behalf of the AMALGAMATED ASSOCIATION OF WIRE AND STEEL TIN WORKERS OF NORTH AMERICA, or its successors (hereinafter referred to as the “Union”) employed by the Company,

WITNESSETH:

SECTION 1. It is the intent and purpose of the parties hereto that this agreement will promote and improve industrial and economic relations between the employees who are members of the Union and the Company, and to set forth herein the basic agreement covering rates of pay, hours of work, and conditions of employment to be observed by the parties hereto.

It is understood and agreed that for the present time this agreement pertains to all men employed in the Company’s steel plant and wire mill. It is recognized, however, that the plant unit may not always be appropriate, and should circumstances arise which make a change from the plant unit desirable, the plant, by mutual agreement, may be divided into such bargaining units as may from time to time be appropriate.

The term “employee” as used in this agreement shall not include foremen, assistant foremen, or superintendents in charge of any classes of labor, watchmen, salaried employees, or confidential personnel.

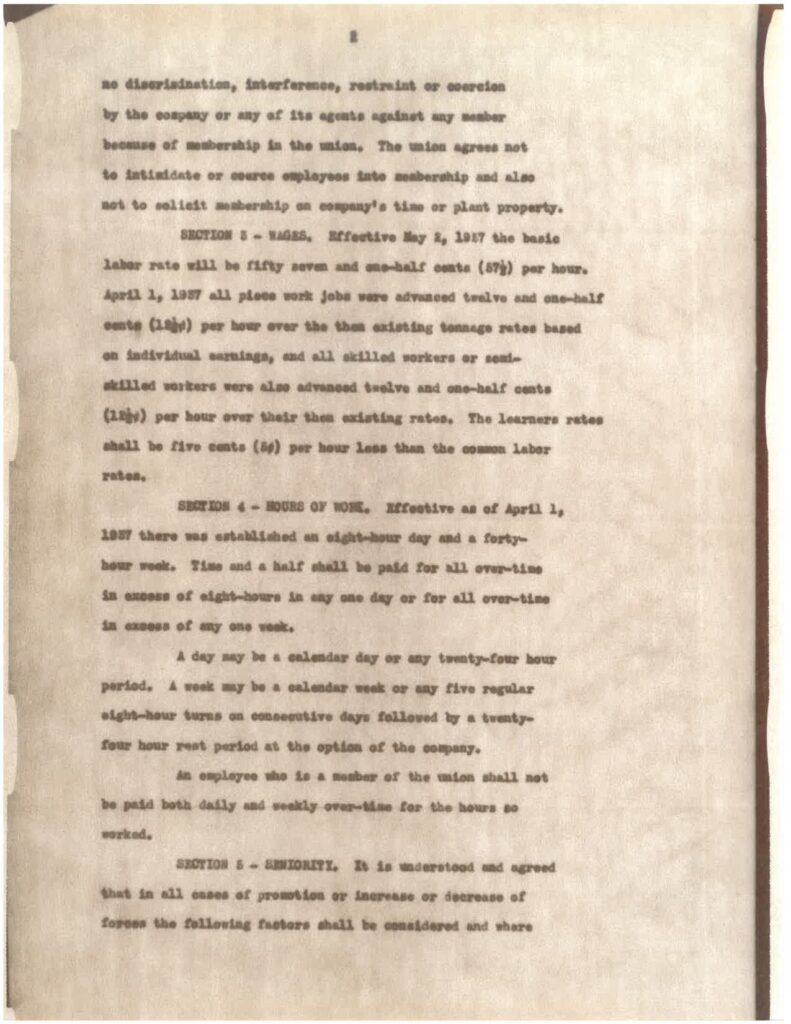

SECTION 2. The Company recognizes the Union as the collective bargaining agency for the employees of the Company. The Company recognizes and will not interfere with the rights of its employees to become members of the Union. There shall be no discrimination, interference, restraint, or coercion by the Company or any of its agents against any member because of membership in the Union. The Union agrees not to intimidate or coerce employees into membership and also not to solicit membership on Company time or plant property.

SECTION 3 – WAGES. Effective May 2, 1937, the basic labor rate will be fifty-seven and one-half cents ($0.575) per hour. As of April 1, 1937, all piecework jobs were advanced twelve and one-half cents ($0.125) per hour over the then-existing tonnage rates based on individual earnings. Additionally, all skilled or semi-skilled workers were advanced twelve and one-half cents ($0.125) per hour over their then-existing rates. The learners’ rates shall be five cents ($0.05) per hour less than the common labor rates.

SECTION 4 – HOURS OF WORK. Effective as of April 1, 1937, there was established an eight-hour day and a forty-hour week. Time and a half shall be paid for all overtime in excess of eight hours in any one day or for all overtime in excess of forty hours in any one week.

A day may be a calendar day or any twenty-four-hour period. A week may be a calendar week or any five regular eight-hour shifts on consecutive days followed by a twenty-four-hour rest period at the option of the Company.

An employee who is a member of the Union shall not be paid both daily and weekly overtime for the hours so worked.

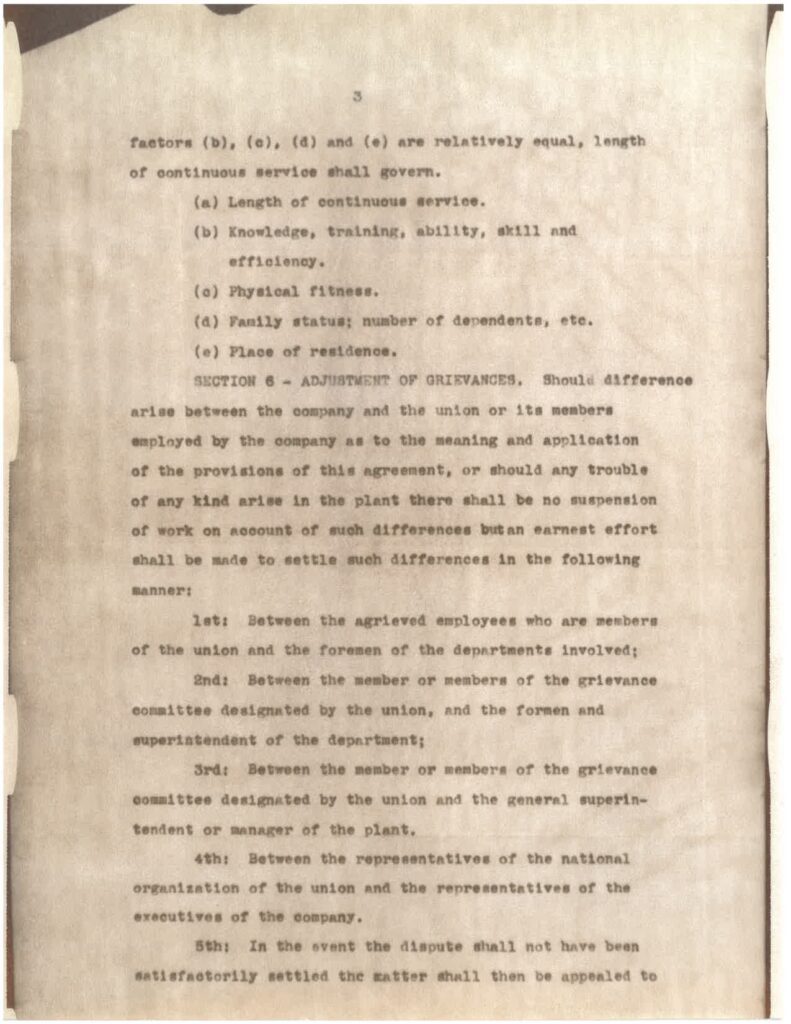

SECTION 5 – SENIORITY. It is understood and agreed that in all cases of promotion or increase or decrease of forces, the following factors shall be considered, and where factors (b), (c), (d), and (e) are relatively equal, length of continuous service shall govern:

(a) Length of continuous service.

(b) Knowledge, training, ability, skill, and efficiency.

(c) Physical fitness.

(d) Family status; number of dependents, etc.

(e) Place of residence.

SECTION 6 – ADJUSTMENT OF GRIEVANCES. Should differences arise between the Company and the Union or its members employed by the Company as to the meaning and application of the provisions of this agreement, or should any trouble of any kind arise in the plant, there shall be no suspension of work on account of such differences, but an earnest effort shall be made to settle such differences in the following manner:

- Between the aggrieved employees (who are members of the Union) and the foremen of the departments involved;

- Between the member(s) of the grievance committee designated by the Union, and the foremen and superintendent of the department;

- Between the member(s) of the grievance committee designated by the Union and the general superintendent or manager of the plant;

- Between the representatives of the national organization of the Union and the representatives of the executives of the Company;

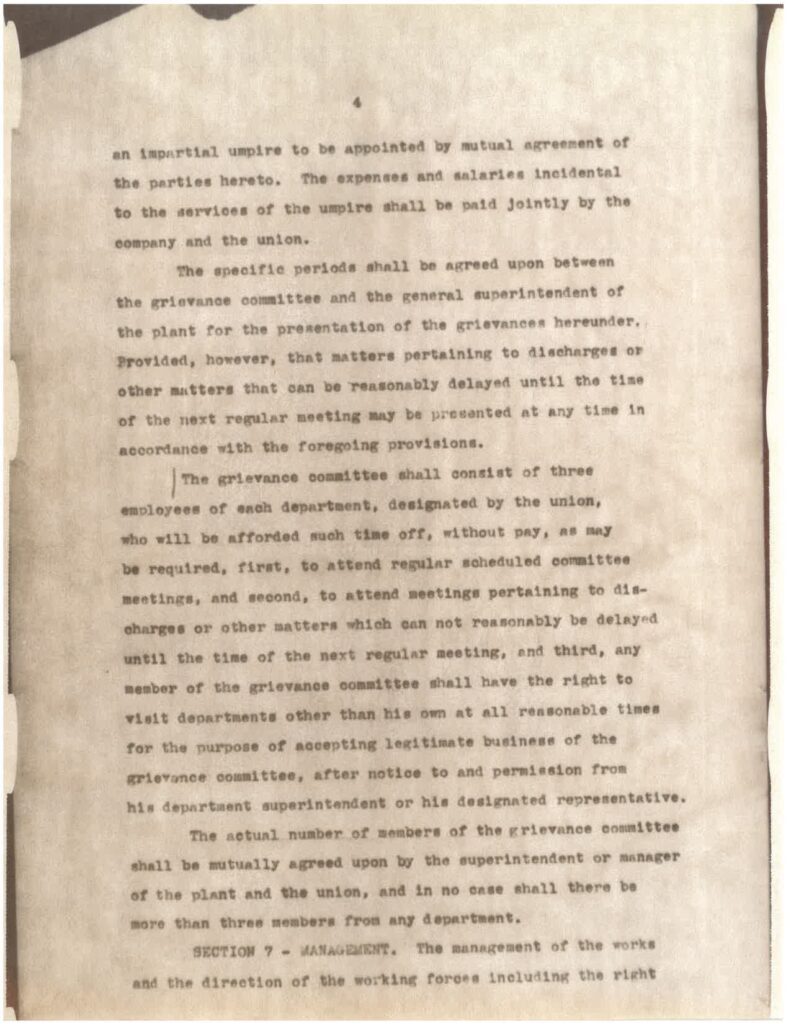

- In the event the dispute shall not have been satisfactorily settled, the matter shall then be appealed to an impartial umpire to be appointed by mutual agreement of the parties hereto. The expenses and salaries incidental to the services of the umpire shall be paid jointly by the Company and the Union.

The specific periods shall be agreed upon between the grievance committee and the general superintendent of the plant for the presentation of grievances hereunder. Provided, however, that matters pertaining to discharges or other matters that cannot be reasonably delayed until the time of the next regular meeting may be presented at any time in accordance with the foregoing provisions.

The grievance committee shall consist of three employees of each department, designated by the Union, who will be afforded such time off, without pay, as may be required: To attend regular scheduled committee meetings; To attend meetings pertaining to discharges or other matters which cannot reasonably be delayed until the time of the next regular meeting; Any member of the grievance committee shall have the right to visit departments other than his own at all reasonable times for the purpose of conducting legitimate business of the grievance committee, after notice to and permission from his department superintendent or designated representative.

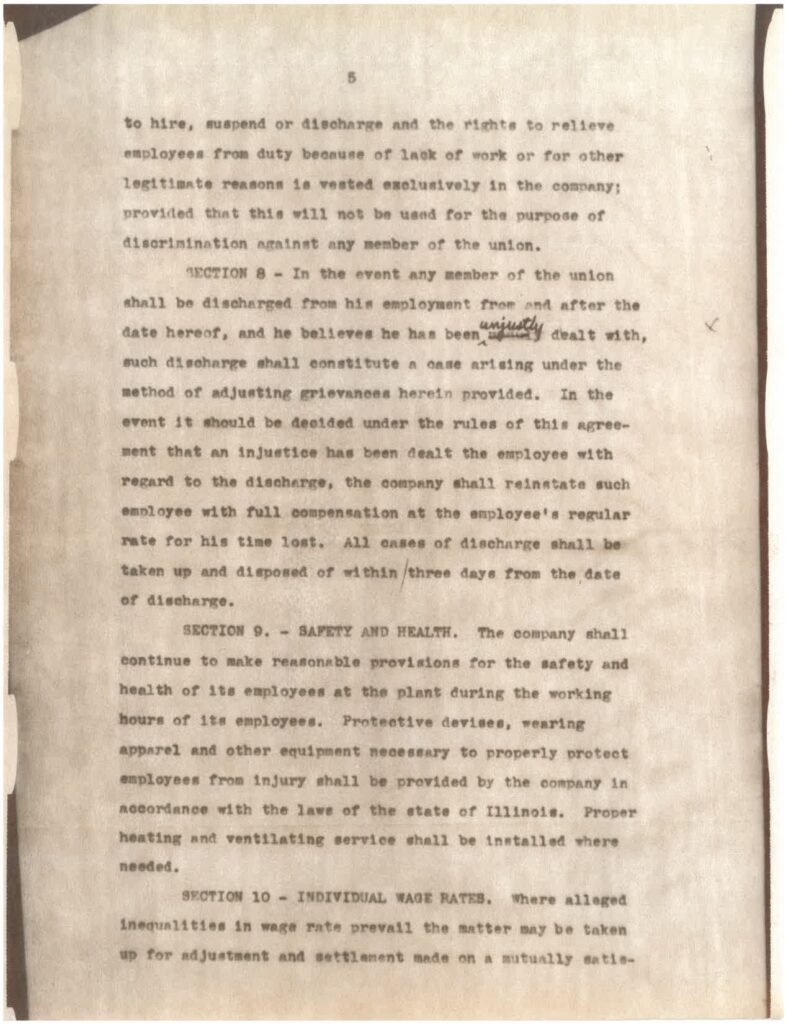

The actual number of members of the grievance committee shall be mutually agreed upon by the superintendent or manager of the plant and the Union, and in no case shall there be more than three members from any department.

SECTION 7 – MANAGEMENT. The management of the works and the direction of the working forces, including the right to hire, suspend, or discharge, and the right to relieve employees from duty because of lack of work or for other legitimate reasons, is vested exclusively in the Company; provided that this will not be used for the purpose of discrimination against any member of the Union.

SECTION 8 – DISCHARGE AND REINSTATEMENT. In the event any member of the Union shall be discharged from his employment from and after the date hereof, and he believes he has been unjustly dealt with, such discharge shall constitute a case arising under the method of adjusting grievances herein provided. In the event it should be decided under the rules of this agreement that an injustice has been dealt the employee with regard to the discharge, the Company shall reinstate such employee with full compensation at the employee’s regular rate for his time lost. All cases of discharge shall be taken up and disposed of within three days from the date of discharge.

SECTION 9 – SAFETY AND HEALTH. The Company shall continue to make reasonable provisions for the safety and health of its employees at the plant during the working hours. Protective devices, wearing apparel, and other equipment necessary to properly protect employees from injury shall be provided by the Company in accordance with the laws of the State of Illinois. Proper heating and ventilating services shall be installed where needed.

SECTION 10 – INDIVIDUAL WAGE RATES. Where alleged inequalities in wage rates prevail, the matter may be taken up for adjustment and settled on a mutually satisfactory basis.

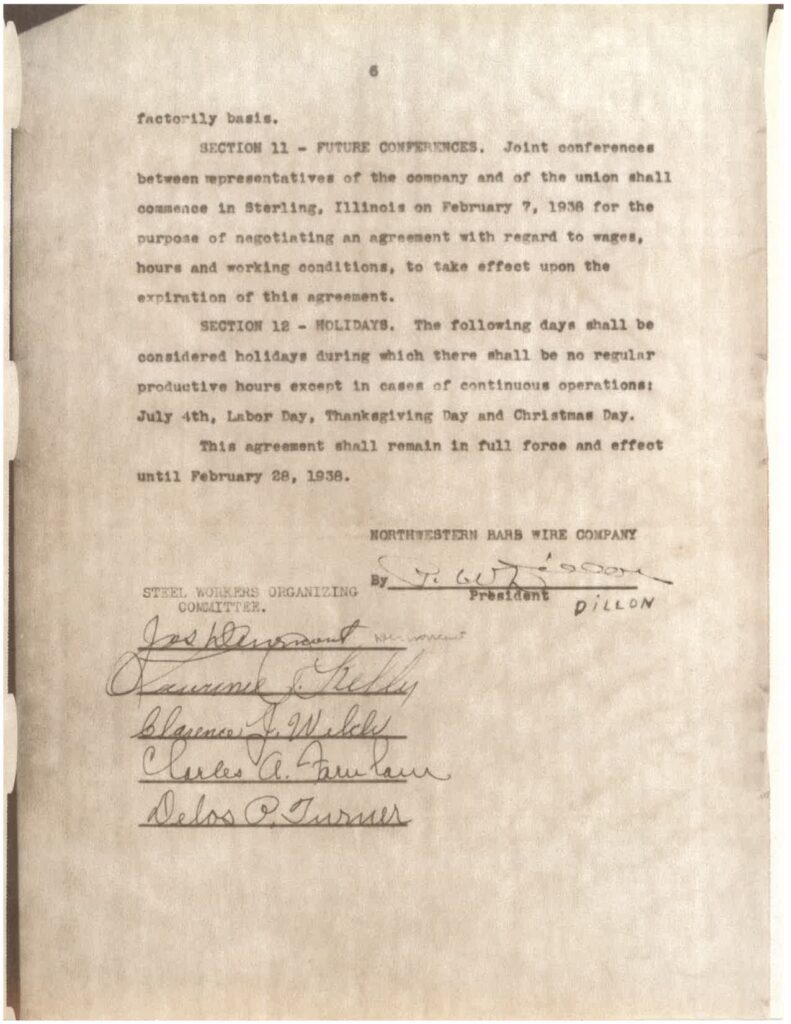

SECTION 11 – FUTURE CONFERENCES. Joint conferences between representatives of the Company and of the Union shall commence in Sterling, Illinois, on February 7, 1938, for the purpose of negotiating an agreement with regard to wages, hours, and working conditions, to take effect upon the expiration of this agreement.

SECTION 12 – HOLIDAYS. The following days shall be considered holidays during which there shall be no regular productive hours, except in cases of continuous operations: July 4th, Labor Day, Thanksgiving Day, and Christmas Day.

This agreement shall remain in full force and effect until February 28, 1938.

NORTHWESTERN BARB WIRE COMPANY

By: P.W Dillon

President

STEEL WORKERS ORGANIZING COMMITTEE

List of signatures